Expansion Joints Design Basics

Design Basics.

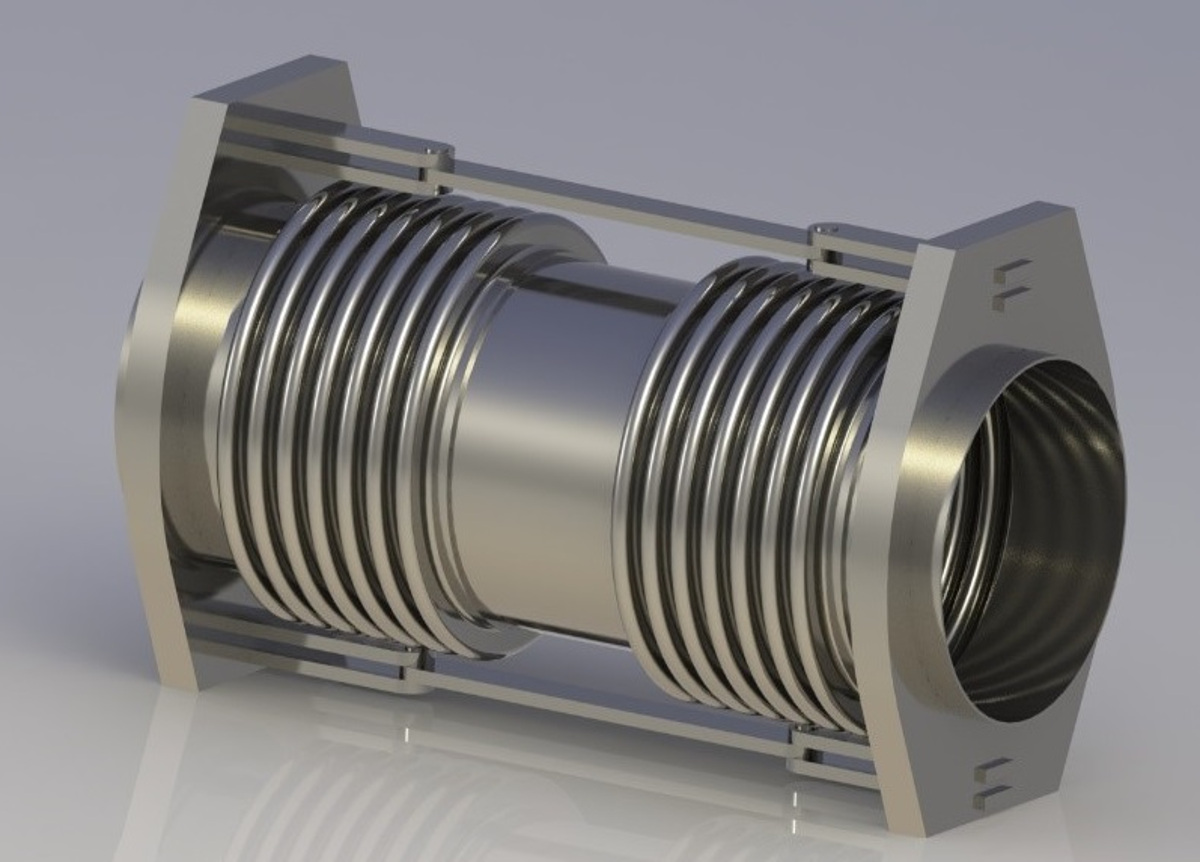

Metal bellows expansion joints consist of a flexible bellows element, appropriate end fittings such as flanges or butt-weld ends to allow connection to the adjacent piping or equipment, and other accessory items that may be required for a particular service application.

All materials expand and contract with thermal change.

Bellows Design

Bellows are manufactured from relatively thin-walled tubing to form a corrugated cylinder. The corrugations commonly referred to as convolutions; add the structural reinforcement necessary for the thin-wall material to contain system pressure. The bellows designer/engineer selects the thickness and convolution geometry to produce a bellows design that approaches, and often exceeds the capacity of the adjoining pipe to contain system pressure at the specified design temperature.

Flexibility of the bellows is achieved through bending of the convolution sidewalls, as well as flexing within their crest and root radii. In most cases, multiple convolutions are required to provide sufficient flexibility to accommodate the expected expansion and contraction of the piping system.

Piping Flexibility

All materials expand and contract with thermal change. In the case of piping systems, the dimensional change can produce excessive stresses throughout the piping system and at fixed points such as vessels, rotating equipment, and as well as within the piping itself.

Movement Capabilities

- Axial Compression: Reduction of the bellows length due to piping expansion.

- Axial Extension: Increase of the bellows length due to pipe contraction.

- Lateral Offset: Transverse motion, which is perpendicular to the plane of the pipe with the expansion joint, ends remaining parallel.

- Angular Rotation: Bending about the longitudinal centerline of the expansion joint.